Drains are a vital part of the infrastructure that helps manage the disposal of waste and controls the flow of water. Without maintaining good quality of drains and pipes, the health and safety of communities can be endangered and our environment unprotected. Structural and environmental damages, health hazards and high-cost repairs are only some of the potential consequences of failing to maintain the good quality of your drains and pipes.

In this blog, we share 5 ways of maintaining your drains and keeping them healthy.

Let’s dive in.

5 tips to maintain the good quality of your drains

Regular Inspections

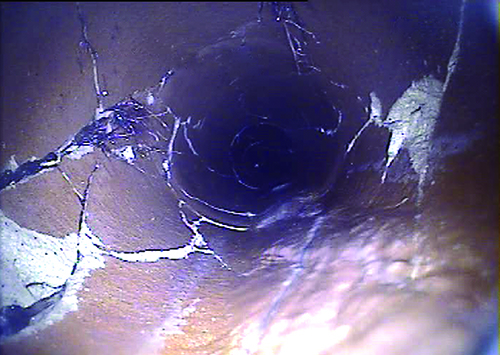

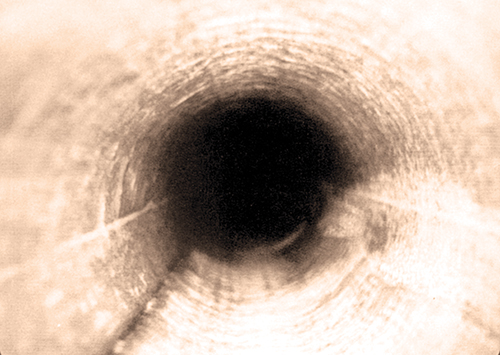

Regular inspections are essential for maintaining the quality of pipes and drains. Preventative maintenance can help identify potential issues before they become significant and costly problems. Inspections can help identify any potential problems before they become severe and lead to expensive repairs. This is particularly important after heavy rain or storms when flooding can lead to blockages caused by debris and rapid pipe erosion. The most effective way to inspect drains is by using CCTV inspection cameras. Engineered to travel through pipes and capture high-resolution images and thereby precise diagnosis of any damage to the sewer system, CCTV inspection cameras offer an efficient and cost-effective solution.

Proper Disposal of Waste

Certain materials such as fat, oil, grease, and other waste should never be poured down the drain, as they can cause significant damage to sewer systems and lead to the formation of fatbergs which has been a growing issue. Non-Biodegradable items such as sanitary products should never be flushed as they can cause blockages in drains and pipes. Wet wipes, for example, are the single biggest cause of fatbergs that block sewage systems. Furthermore, these items often contain plastic and when flushed can negatively affect the environment.

Tree (roots) Management

Tree roots are one of the main reasons why pipes get blocked and can cause serious damage and blockages to pipes and drains. Tree root management includes regular trimmings and pruning, on average 3-5 years or more often, depending on the type, age and size of the tree. A good rule of thumb is to ensure that trees are not planted too close to drains and pipes (at least 3 meters away). If this is unavoidable, installing root barriers to prevent roots from growing towards drains and pipes can prevent damage.

Regular Cleaning

Cleaning drains and pipes at least once a year is one of the essential steps in maintaining the good quality of pipes and drains. Over time, drains accumulate debris and deposit, which can in return cause permanent damage. Proper use of harsh chemicals is very important too, as otherwise these can cause health hazards and affect the quality of your pipes and drains. This can be prevented by always following the manufacturer’s instructions.

Professional Maintenance

There are many advantages to hiring a professional plumber and drain cleaning company. They have the experience and expertise needed to diagnose any potential and existing drain issues and offer customised solutions quickly and efficiently. Trained and reputable professionals can help prevent costly damages caused by improper use of tools and equipment and stand behind their work if something goes wrong.

Advantages of Scanprobe drain cameras

Our range of drain inspection camera systems have been engineered with the pipeline inspection industry in mind, and so they are packed with design features to complement each individual job and condition.

From the industry favourite Maxprobe to mina, our survey reporting software and Scanprobe X40 that comes with multiple control & surveying options, our products guarantee powerful surveys. We keep developing premium-quality products and that way leading the way with the latest product innovations.

Get in touch with our team for a free-of-charge consultation or a quote and find out more about how our range of products and services can make a difference in your next inspection.